ZePrA | Auto Setup EN

Auto Setup

Workflow Creation

ZePrA provides several auto setup methods to set up workflows for the most common color management tasks. The Automatic Setup Wizard also allows workflows that save ink, optimize the total area coverage (TAC), apply gradation corrections and proofing. It takes just a few steps to create Configurations and Queues.

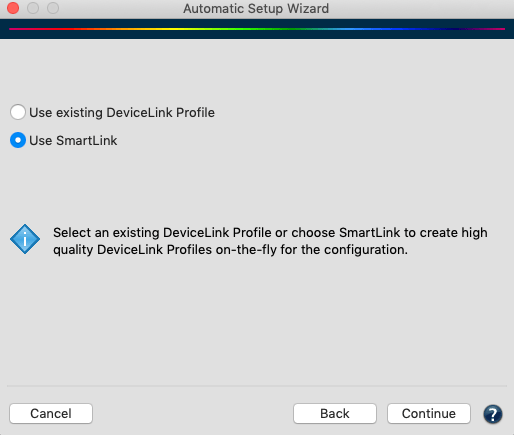

To process files, either use a previously created DeviceLink profile, or use the SmartLink function to create a DeviceLink profile on-the-fly (SmartLink license required).

Setting Up Workflows with the Auto Setup Wizard

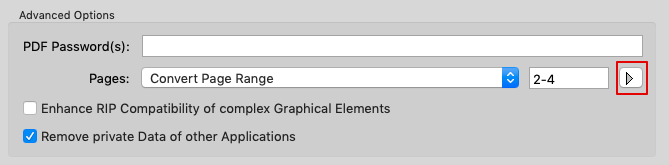

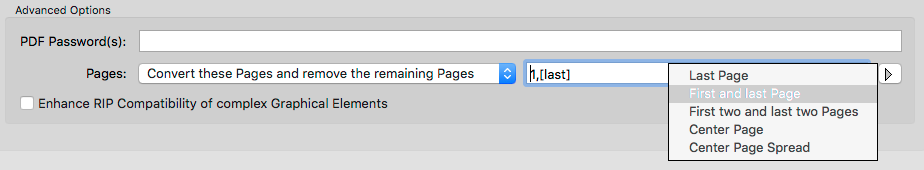

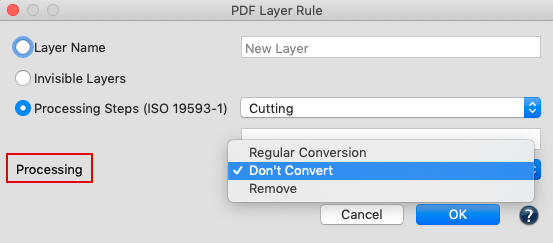

Select Auto Setup in the sidebar. There are seven different setup options for creating Configurations and Queues. The first two modes involve normalizing the data. General Information about Normalizing Data can be found further down this page.

Select a Setup Mode

Normalize and convert Colors to new Output Condition

The content of the PDF file is first normalized to the document color space or output intent and then converted to the desired target color space.

PDF files usually do not contain any information about the document color space. If there is no PDF/X file available for Normalization but only a PDF file, decide on a Document Color Space into which any existing ICC-based PDF objects will be converted.

There are two options to choose from:

- Use existing DeviceLink Profile

Choose a DeviceLink profile for the configuration (e.g. from our DeviceLink sets, available from any ColorLogic dealer), and select it from the drop-down menu. The source and target profiles are set by the DeviceLink profile.

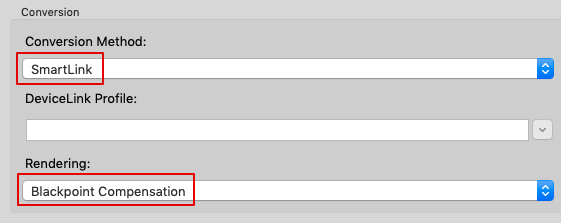

- Use SmartLink

The SmartLink function creates DeviceLinks on-the-fly from source and target profiles.

Note: Requires a SmartLink license. If the SmartLink function is not available, normal ICC conversions are performed for objects with embedded ICC profiles.

For more information, see DeviceLink or SmartLink further down on this page.

Select the rendering intent for the calculation. More information can be found further down this page under Rendering Intent.

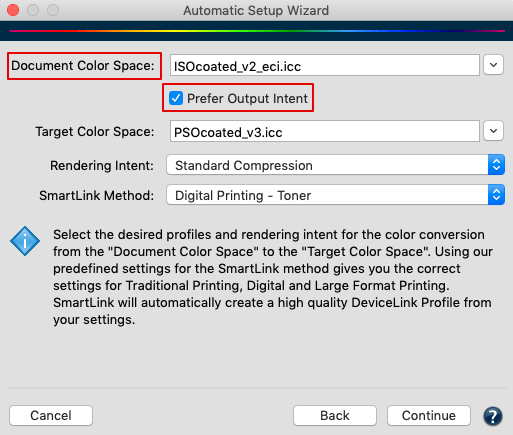

Prefer Output Intent: The output intent of the PDF/X file is used instead of the manually set document color space.

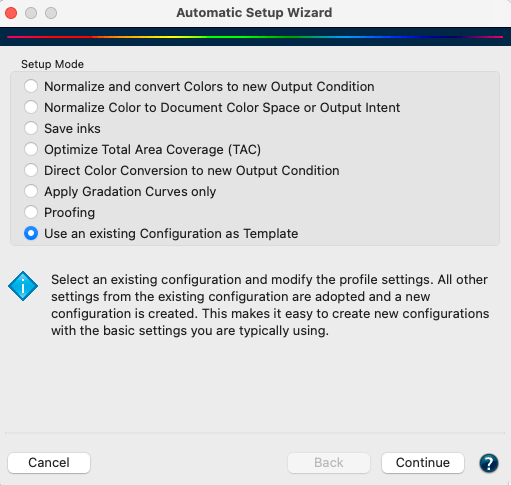

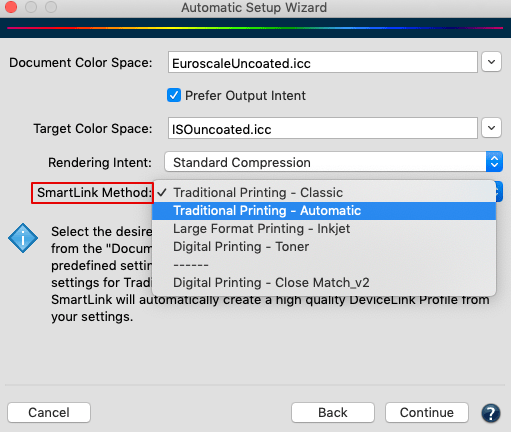

SmartLink Method: Defines the conversion settings. There are predefined methods available for traditional printing, large format printing, and digital printing, but custom methods can also be used.

Data processing:

RGB objects with embedded profiles are first converted to the document color space (normalized). If the SmartLink function is activated and an individual PDF object contains an embedded device profile, the device profile is used to create a DeviceLink profile on-the-fly. Embedded rendering intents are also considered. When normalizing, all images without embedded profiles are converted to the document color space based on the predefined profile.

CMYK objects with embedded profiles are first converted to the document color space (normalized). If the SmartLink function is activated and an individual PDF object contains an embedded device profile, the device profile is used to create a DeviceLink profile on-the-fly. The conversion is then performed using this DeviceLink profile.

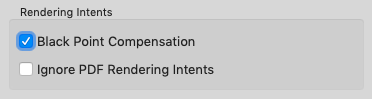

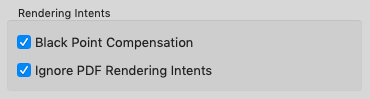

If a Relative Colorimetric rendering intent is embedded in a PDF object, Auto Setup automatically activates the Blackpoint Compensation to ensure clean reproduction of details in the shadow areas.

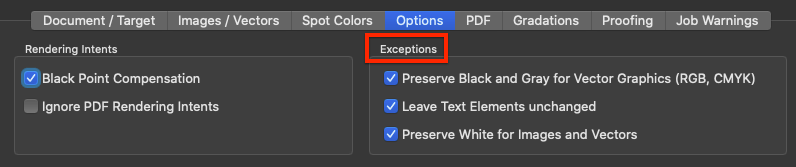

Exception: PDF 2.0 files – see Black Point Compensation with PDF 2.0 files under Configurations/Options/Rendering Intents.

If the DeviceLink profile was created using the option to preserve pure primaries and secondaries, pure colors are kept pure in CMYK objects with embedded profiles.

To ensure precise color conversions, ZePrA completely recalculates the conversion of source and target profiles on-the-fly. The algorithms used are identical to those used in ColorLogic’s CoPrA profiling software.

There are five additional rendering intents available for SmartLink to avoid inharmonic color conversions that can result from differently calculated tables for source and target profiles (see Rendering Intents).

If SmartLink has not been licensed, a direct ICC-based conversion to the target profile or document color space is performed. This can contaminate pure CMYK colors, which can cause problems with overprinting elements.

The automatic setup wizard’s option to normalize first and convert afterwards provides the most consistent results for color conversions, as recommended by the PDF/X specification.

The default name of this queue starts with Convert.

Normalize Color to Document Color Space or Output Intent

The data is standardized, i.e. it is converted to the document color space or output intent (normalized).

For PDF files, all ICC-based PDF objects are converted from the embedded ICC profile via the embedded rendering intent to the document color space (output intent). After this step, all objects of the PDF file are color-matched to a consistent standard (document color space/output intent).

PDF files usually do not contain any information about the document color space. If there is no PDF/X file available for Normalization but only a PDF file, decide on a Document Color Space into which any existing ICC-based PDF objects will be converted.

After conversion, the final, normalized file consists only of a document color space and spot colors, if present.

If a Relative Colorimetric rendering intent is embedded in a PDF object, Auto Setup automatically activates the Blackpoint Compensation to ensure clean reproduction of details in the shadow areas.

Exception: PDF 2.0 files – see Black Point Compensation with PDF 2.0 files under Configurations/Options/Rendering Intents.

The following color conversions are performed during normalization:

- Conversion of device RGB and ICC-based RGB objects to document color space

- Spot colors remain unchanged (can be converted to the target color space if required)

- Conversion of ICC-based CMYK to document color space, retaining pure colors and separation properties (when using SmartLink)

- Assignment of ICC-based gray to the black channel of the document color space (prevents four-color gray)

The default name of these queues start with Normalize.

Save inks

The data is first normalized to the document color space and then optimized using either an existing SaveInk profile or a SmartLink SaveInk method. Three Ink Saving methods are available.

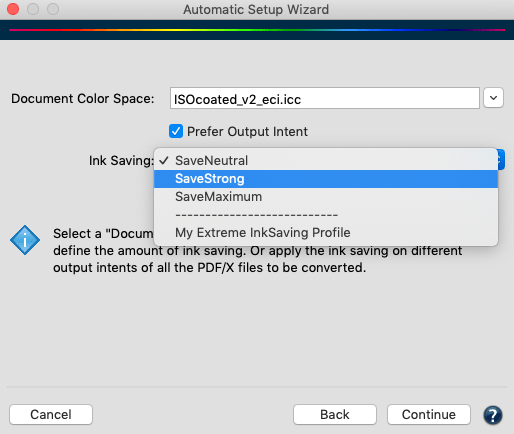

Selecting an Ink Saving method

The Save inks setup mode is available when the source and target profiles are identical. The optimized file remains in the same color space. The focus is on accurate color reproduction while reducing CMY inks and increasing black ink (K).

Use existing DeviceLink Profile: Select an existing SaveInk DeviceLink profile from the drop-down menu. ZePrA only shows profiles whose source and target profiles are identical.

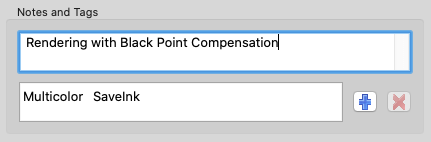

Use SmartLink: Select the profile which matches the Document Color Space and choose from three standard Ink Saving methods (SaveNeutral, SaveStrong, SaveMaximum). It is also possible to define custom SaveInk settings in CoPrA and share them with ZePrA. These custom SaveInk settings are displayed below the dashed line (My Extreme InkSaving Profile in the screenshot above).

SaveNeutral: Moderately increases the amount of black in the neutral color ranges.

SaveStrong: Increases the proportion of black strongly.

SaveMaximum: Maximum ink savings with colorimetrically still very high accuracy while retaining the visual color impression.

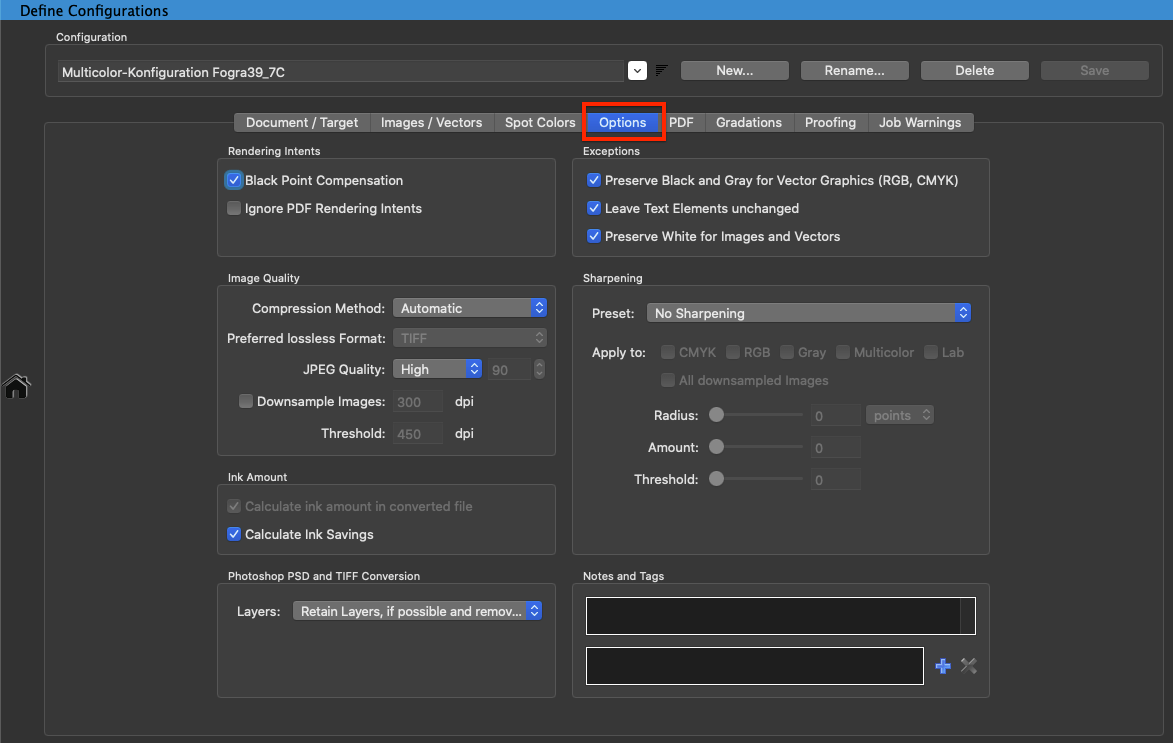

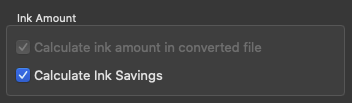

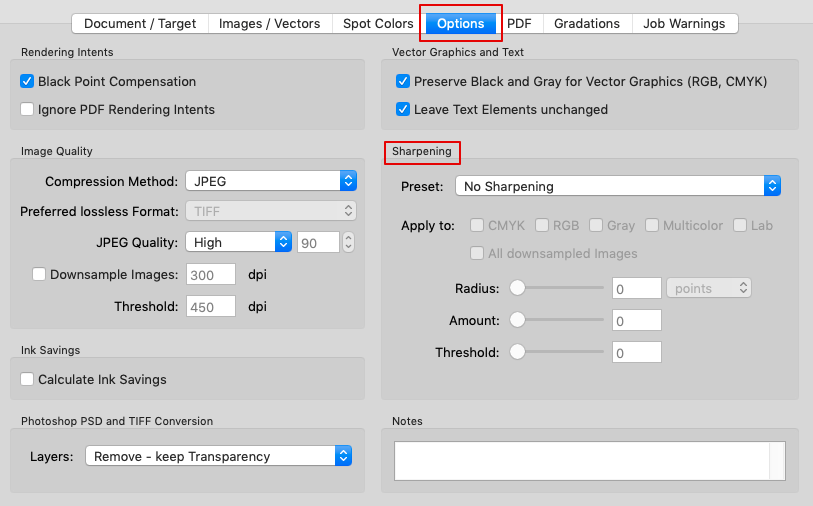

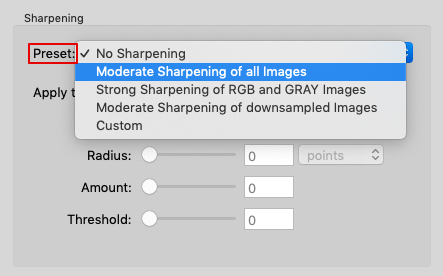

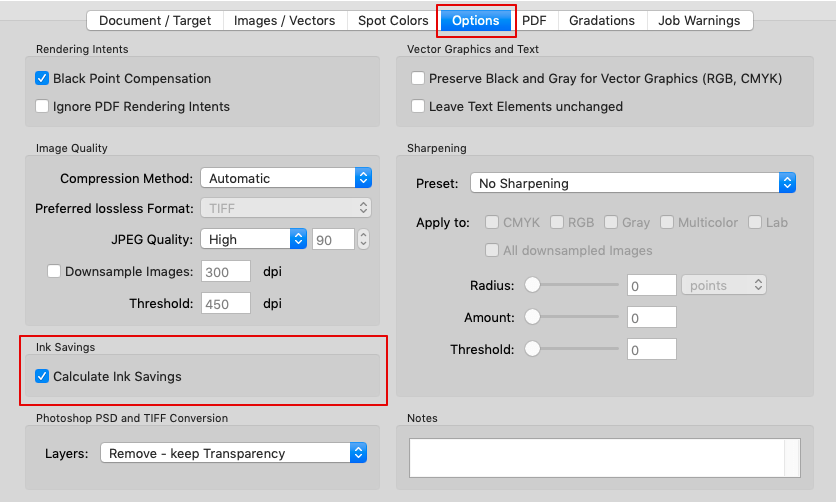

Calculate Ink Savings: The Automatic Setup Wizard can calculate the ink savings for processed files. However, this calculation can significantly slow down processing. If faster data processing is desired, deactivate this option.

Note: The ink saving calculation can be enabled or disabled under Configurations/Options.

The default queue name starts with SaveInk.

Optimize Total Area Coverage (TAC)

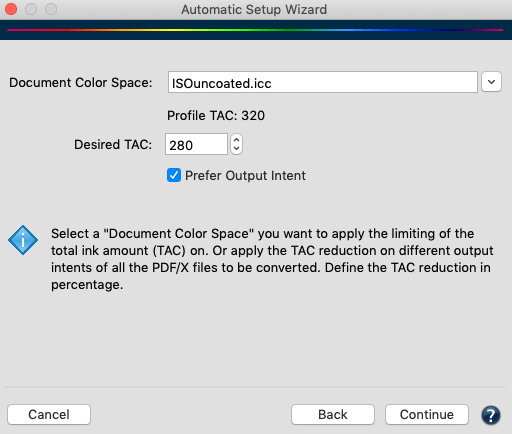

The data is normalized to the document color space and the total amount of ink is reduced. This can either be done by using special profiles to reduce the total area coverage (TAC), or – if SmartLink is used – by specifying the Desired TAC value.

Adjusting the maximum ink coverage

The source and target profiles must be identical. The optimized file remains in the Document Color Space. The focus is on accurate color reproduction while reducing ink coverage.

Choose from two options:

- Use existing DeviceLink Profile: Select an existing TAC reduction DeviceLink profile from the drop-down menu. ZePrA only displays profiles with identical source and target profiles.

- Use SmartLink: Assigns a TAC to the selected Document Color Space on-the-fly (requires a SmartLink license).

Prefer Output Intent: The output intent of the PDF/X file is used instead of the manually set Document Color Space.

The default name of these queues starts with TAC.

Direct Color Conversion to new Output Condition

The data is directly converted to the target color space using embedded profiles, without normalizing to the document color space beforehand. This setup mode enables the best color space utilization of the target color space and is particularly suitable for media-neutral data, e.g. RGB image data with ICC profiles.

If the profile embedded in the file matches the profile defined as Document Color Space, the profile setting defined in the Document/Target tab is used instead of the settings in the Image/Vector tab.

In addition, the rendering intents of the PDF are ignored (the Ignore PDF Rendering Intent checkbox in the Options tab is enabled) and the rendering intents defined in the Image/Vector tab are used instead, which usually leads to an improved color rendering for direct color conversions.

Select either Use existing DeviceLink Profile or Use SmartLink.

Use existing DeviceLink Profile: Select a DeviceLink profile that converts from the document color space to the required output condition. All other settings for RGB, CMYK, Gray and Lab color spaces are set automatically.

Use SmartLink: Select the respective ICC profiles under Document Color Space and Target Color Space to create the DeviceLink on-the-fly. Define the intended Rendering Intent and the SmartLink Method that best fits your workflow process.

RGB objects with embedded profiles: Converts directly to the target color space and utilizes the maximum color space, however, the embedded profiles and the selected Rendering Intent are taken into account. This guarantees a consistent conversion and optimization of the data.

RGB data without embedded profiles: The sRGB color space is used, which can be changed in the configuration, if necessary.

In general, Blackpoint Compensation is enabled when the embedded intent is Relative Colorimetric.

CMYK objects with embedded profiles: The SmartLink function optimizes direct color conversion via the DeviceLink profiles. Embedded profiles/intents are considered.

The default queue name starts with Output.

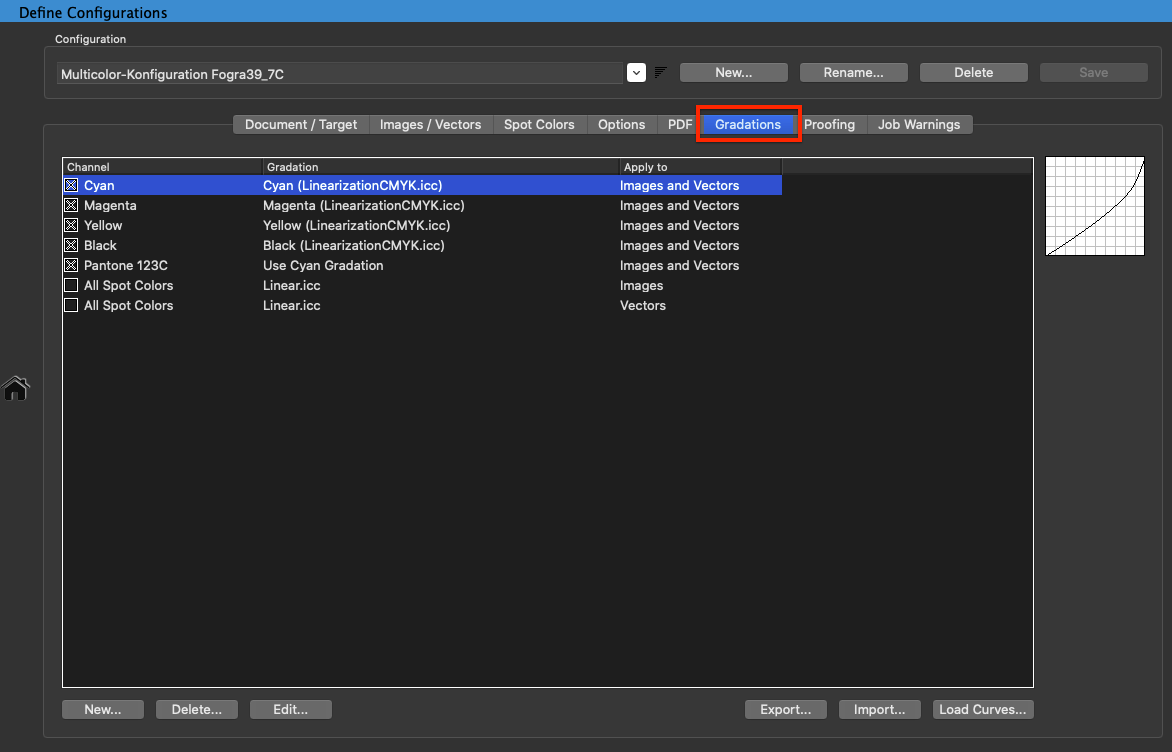

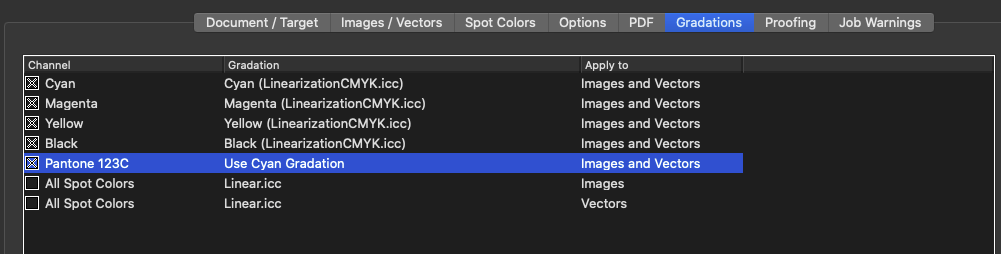

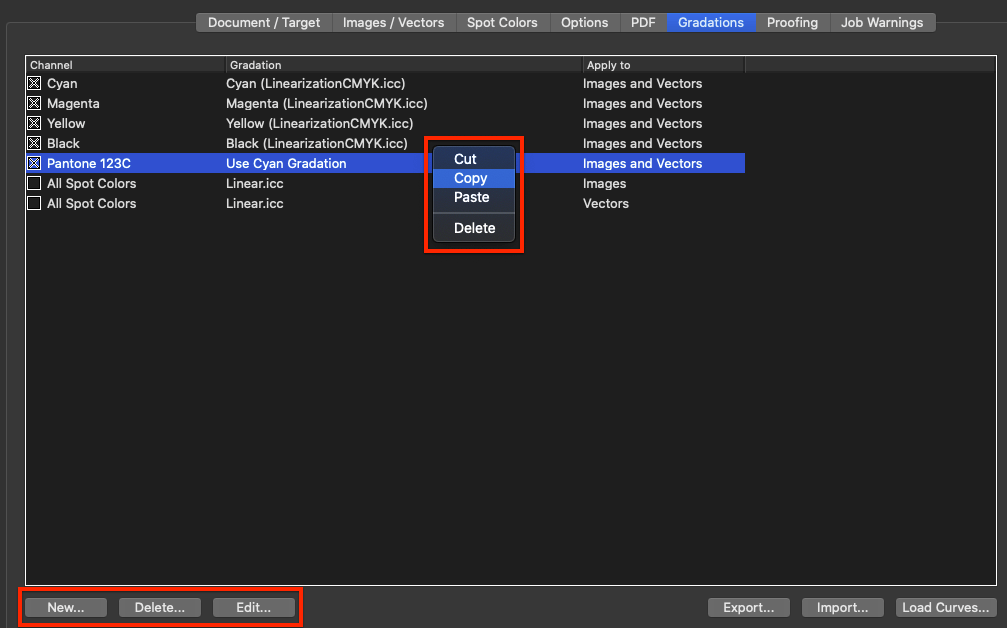

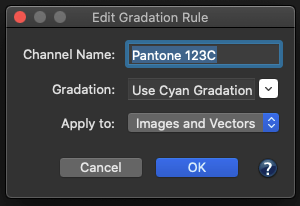

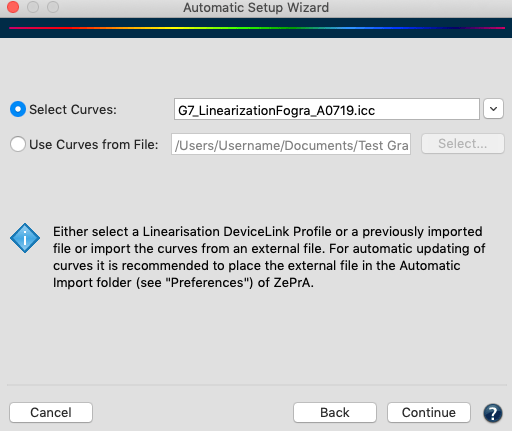

Apply Gradation Curves only

Gradation adjustments apply external files on-the-fly to existing curves, adjusting process colors and/or spot colors without changing the document color space.

Gradation curves are a simple solution for applying gradation corrections to print-ready PDF/X-1a files consisting of CMYK and spot colors only.

There are two ways to correct gradations:

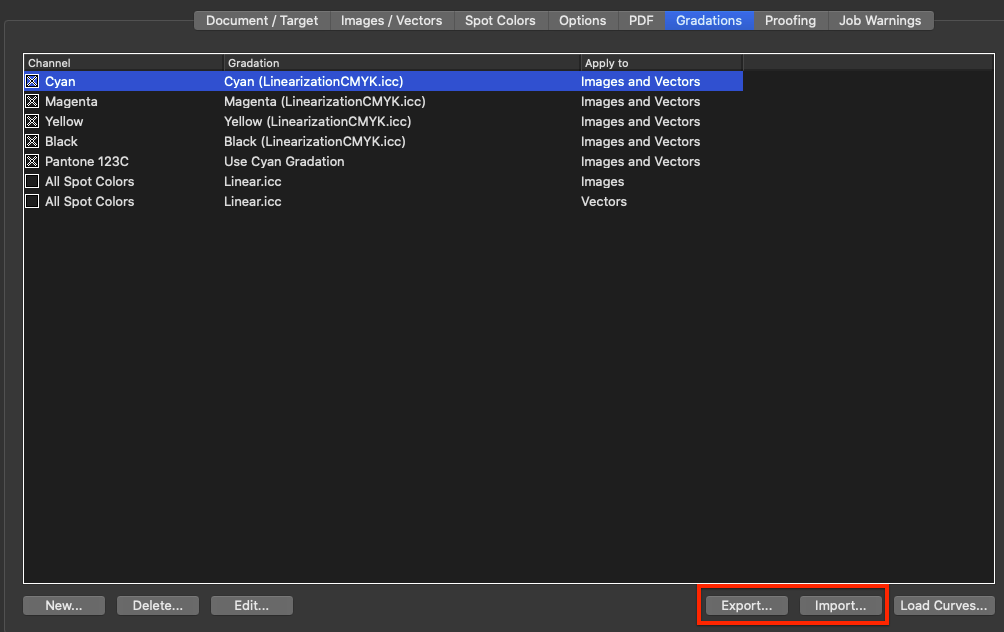

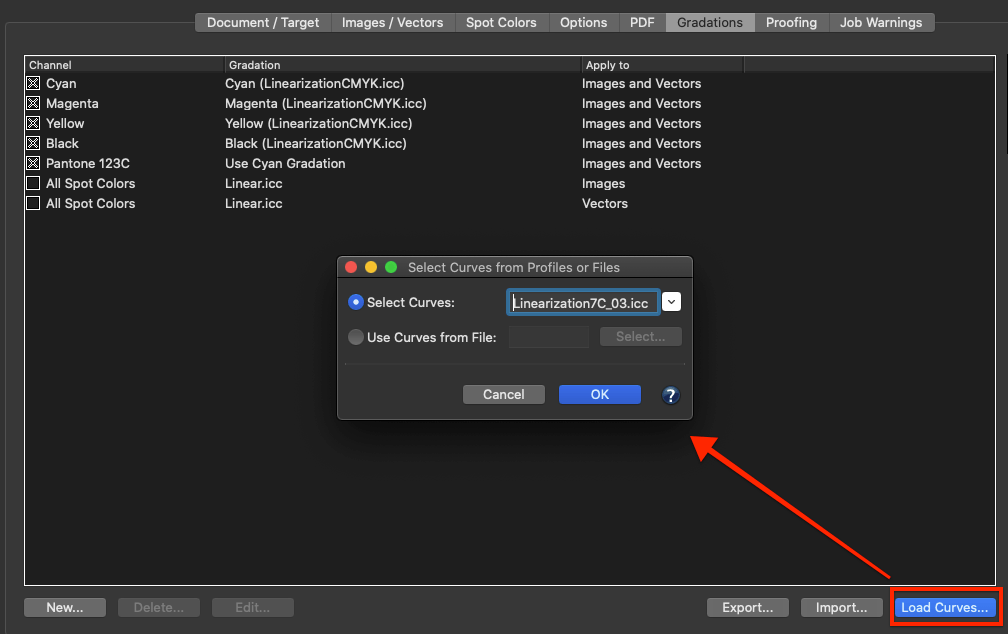

1: Select Curves

Select Linearization DeviceLinks created by CoPrA or previously imported files including curves (gradations). Previously imported files will be shown beneath the linearization DeviceLink profiles.

Gradation curves created with CoPrA’s Linearization tool are saved in the Profiles folder (/User/User name/Library/ColorSync/Profiles oder C:/WINDOWS/system32/spool/drivers/color/) and are automatically listed in ZePrA’s Select Curves drop-down menu. Only curves with a matching color space are shown. These curves are read only and cannot be edited with ZePrA’s Gradations tool. When changing the gradation curves (e.g. by overwriting the .icc file in CoPrA with differing linearization data), these changes will automatically be applied to all configurations using these curves. The location of the selected .icc file is not relevant (e.g. Profile or Auto Import folder).

2: Use Curves from File

Loads an external file that includes the gradation corrections for the process color(s) to be changed.

Gradation curves created with ZePrA’s Gradations tool are saved in the Profiles folder and are automatically listed in the Gradations tab drop-down menu under New/Edit. The curves can also be accessed by Load Curves/Use Curves from File . When changing the gradation curves with ZePrA’s Gradation tool, these changes will automatically be applied to all configurations using these curves.

Normalize and Document Color Space

Normalize: PDF/X-3 or PDF/X-4 files that contain RGB or CMYK objects with embedded profiles are normalized and the curves are applied to the normalized file.

Document Color Space: Define an ICC profile as the document color space for files with no output intent defined in the PDF file. Activate the Prefer Output Intent checkbox to ensure that any existing output intent always takes precedence over the specified document color space and is thus retained.

The default name for these queues starts with Gradations.

Proofing

ZePrA’s sophisticated technology – e.g. the quality of DeviceLink and SmartLink profiles and the spot color rendering of its advanced spot color module – can be used for proofing as well. This is especially useful as many RIPs do not support CxF/X-4 data and SCTV calibration nor have a spectral color prediction model for spot color rendering.

Procedure

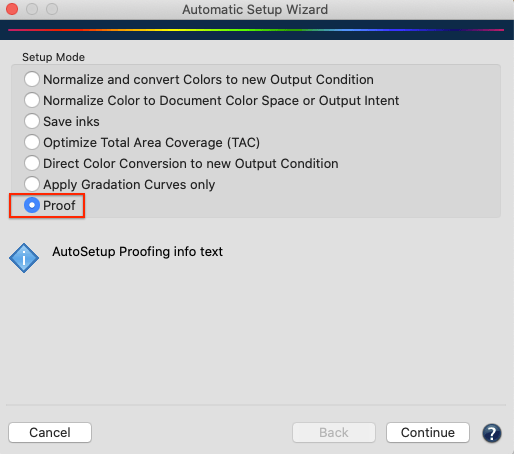

Select Proofing under Setup Mode to create a proofing queue.

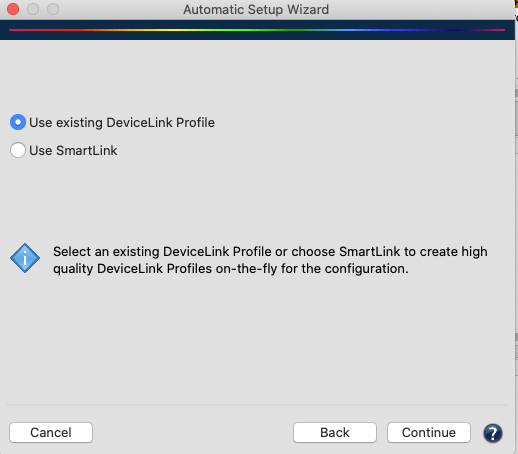

Select either an already created DeviceLink profile for the proof workflow – this can be an iterated DeviceLink profile created by CoPrA – or use SmartLink to create a proof DeviceLink based on your simulation profile and the proofer profile.

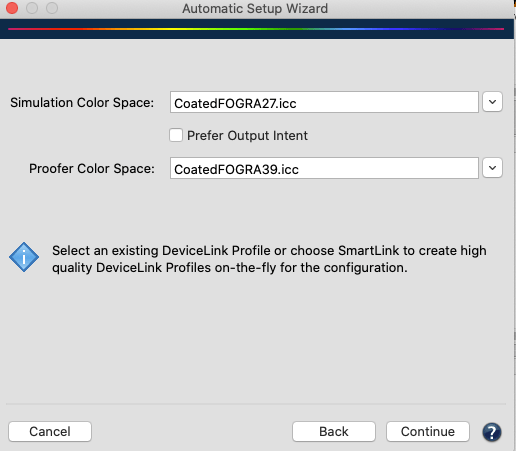

Use SmartLink: The DeviceLink for proofing is created “on-the-fly” based on the Simulation Color Space and the Proofer Color Space. Activate the checkbox Prefer Output Intent to use the output intent of the PDF/X file.

At this point you don’t have to select a rendering intent or SmartLink method as the appropriate settings will be set automatically to achieve best results (e.g. absolute colorimetric rendering and the use of no color exceptions). This includes typical settings for transparency flattening and spot color conversions, too.

If required, the settings can be customized under Configurations once the configuration has been set up, for example to select the desired spot color library for spot color conversion.

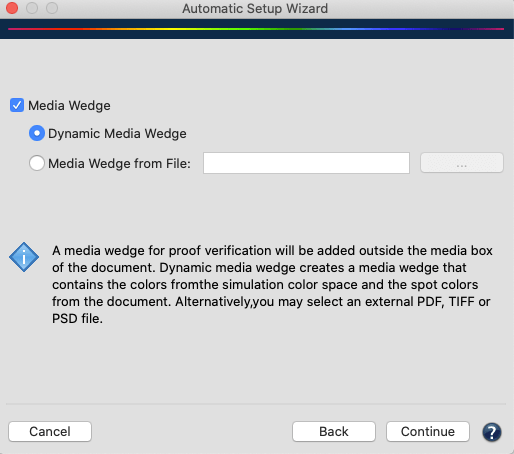

Select a Media Wedge. The media wedge is added outside the media box for proof verification. It can either be a dynamic or an external media wedge.

Dynamic Media Wedge: Uses the colors of the simulation color space and all spot colors of the documents to be processed.

Media Wedge from File: Can be media wedges such as the FOGRA, UGRA, IDEAlliance® or other media wedges (as PDF, TIFF or PSD file).

Note: External media wedges need to be provided (and possibly bought from organisations) by the user. The Idealliance ISO 12647-7: 2013 control wedge for CMYK, Idealliance-3-Row-Digital-Control-Wedge® is available for free. The Idealliance ISO 12647-7 Control Wedge 2013 is included in ZePrA and available under /Users/Shared/ColorLogic/MediaWedges (Idealliance ISO 12647-7: 2013, 3-Row Digital Control Wedge® is a registered trademark of the IDEAlliance®).

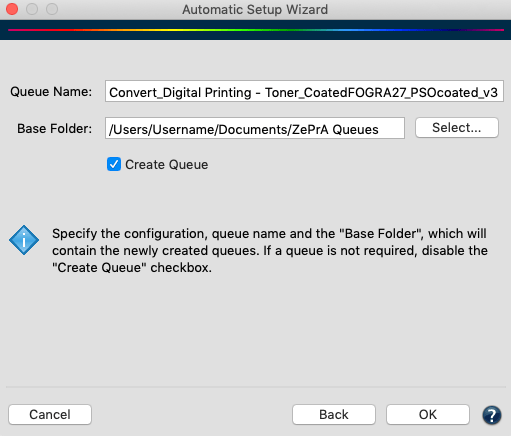

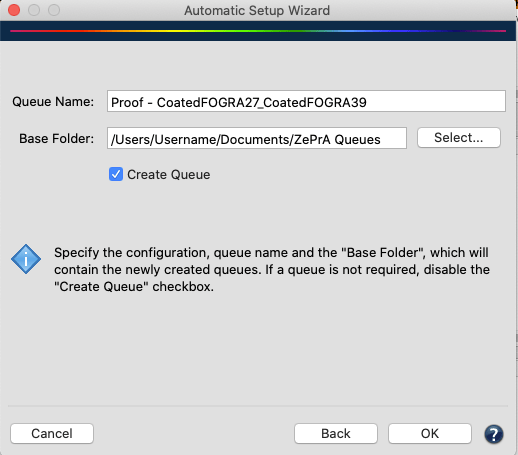

Create the proofing configuration and queue:

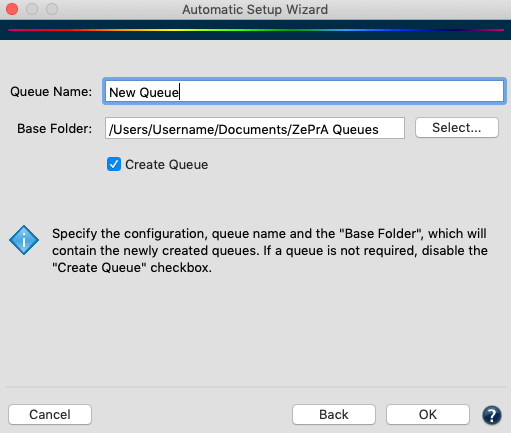

Confirm the Queue Name suggested by ZePrA or enter a custom name.

Specify the Base Folder in which the queue is to be created. To create a Queue (Hotfolder) in the Base Folder, activate the Create Queue checkbox and the corresponding subfolder will be created.

To only create a new configuration, uncheck the Create Queue checkbox. The new configuration can be assigned to an existing queue in the Queues dialog later if required.

Use an existing Configuration as a Template

This Setup Mode uses an existing configuration with all custom settings as a template to create a new valid configuration with only the profiles adjusted. Depending on the profile adjustments made, the settings are modified accordingly to ensure proper functionality of the new configuration:

- When the Document Color Space has changed, the default profile used under Images/Vectors is changed accordingly.

- Iterated spot colors are removed when the target profile has changed (they are kept when the target profile has not changed).

- Correction profiles are deactivated when the target profile has changed (they are kept when the target profile has not changed).

- PDF/X settings are changed when the target profile has changed.

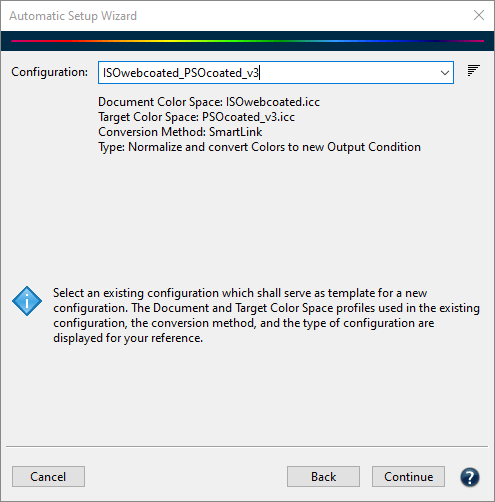

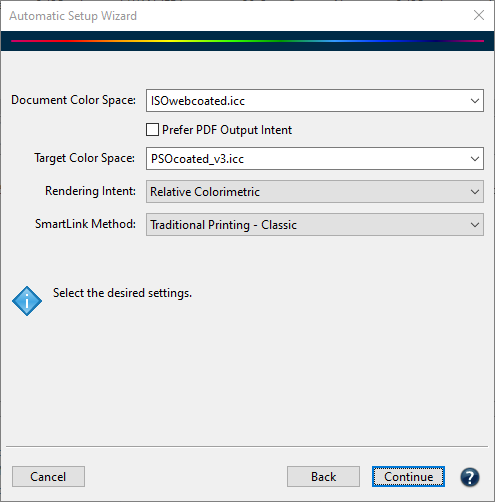

Procedure

First, select the existing configuration to be used as a template. The dialog provides some information about the profiles used as Document and Target Color Space, the Conversion Method, and the configuration Type.

In the next step, new profiles can be selected, which must be of the same color space and type as the original profile, e.g., if the base configuration uses a DeviceLink as the conversion method, the wizard will only allow DeviceLinks to be selected, if the base configuration uses SmartLink, the new configuration will also use SmartLink, etc.

Note: In contrast to the above restriction, when using a SmartLink configuration with Multicolor target profile, Multicolor profiles with other color spaces can also be selected as the new target profile. This is particularly helpful if the Multicolor profile variants created by CoPrA are to be used in ZePrA.

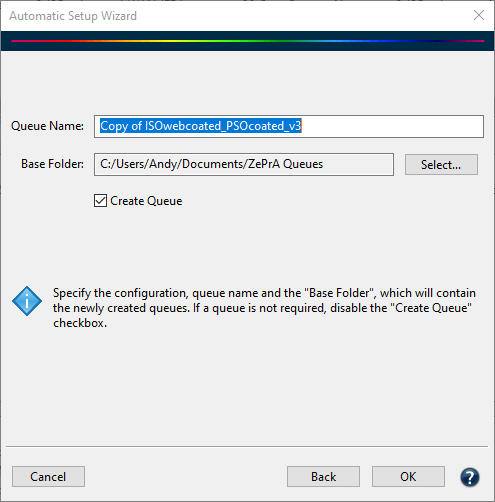

Finally, create the new configuration and queue:

Confirm the Queue Name generated by ZePrA or enter a custom name.

Specify the Base Folder in which the queue is to be created. To create a Queue (Hotfolder) in the Base Folder, select the Create Queue checkbox and the corresponding subfolder will be created.

To only create a new configuration, deselect the Create Queue checkbox. The new configuration can be assigned to an existing queue in the Queues dialog later if required.

DeviceLink or SmartLink

DeviceLink or SmartLink

Either use an existing DeviceLink profile in your configuration or use SmartLink to create and use a high-quality DeviceLink profile within the workflow.

Use existing DeviceLink profile or SmartLink

Use existing DeviceLink Profile

If files are processed without embedded profiles, and there is a matching DeviceLink profile, you can use it within your workflow. This DeviceLink profile then defines the source profile and the target profile.

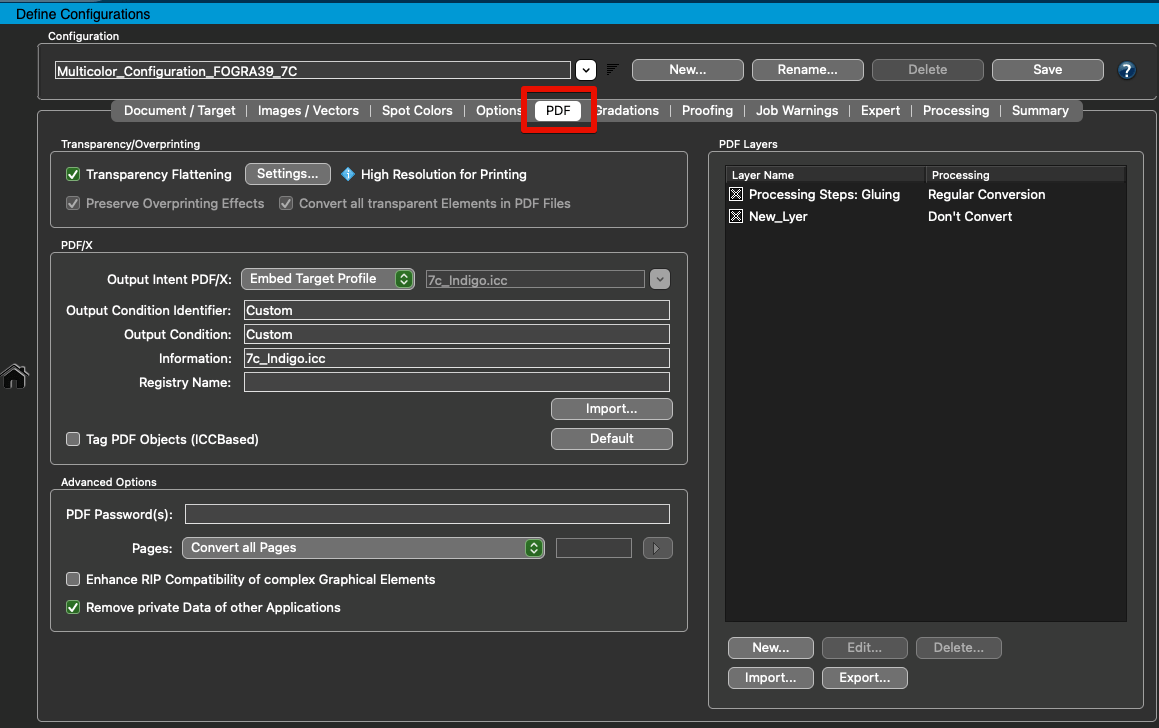

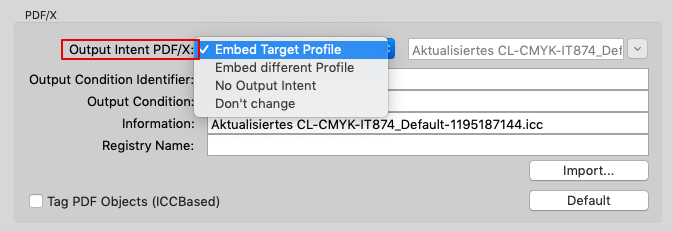

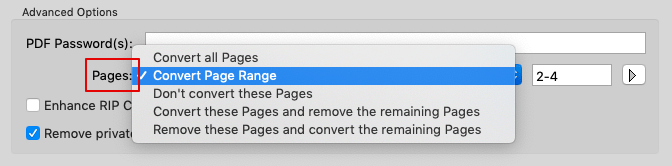

Select the DeviceLink Profile to be used for conversion from the document color space to the target color space. All relevant PDF/X information is automatically transferred. (For more information, see Configurations – PDF/X)

In the Save inks and Optimize Total Area Coverage (TAC) modes, the drop-down menu DeviceLink Profile only lists profiles with identical source and target profiles.

Use SmartLink

The DeviceLink for the conversion is created “on-the-fly” based on source and target profiles. The Rendering Intent for the calculation can be selected manually. Instead of the manually set Document Color Space, read out and use the output intent of the PDF/X file by activating the Prefer Output Intent checkbox.

The SmartLink option creates high quality DeviceLink profiles to avoid the problems of typical ICC conversions and ensures optimal color conversions.

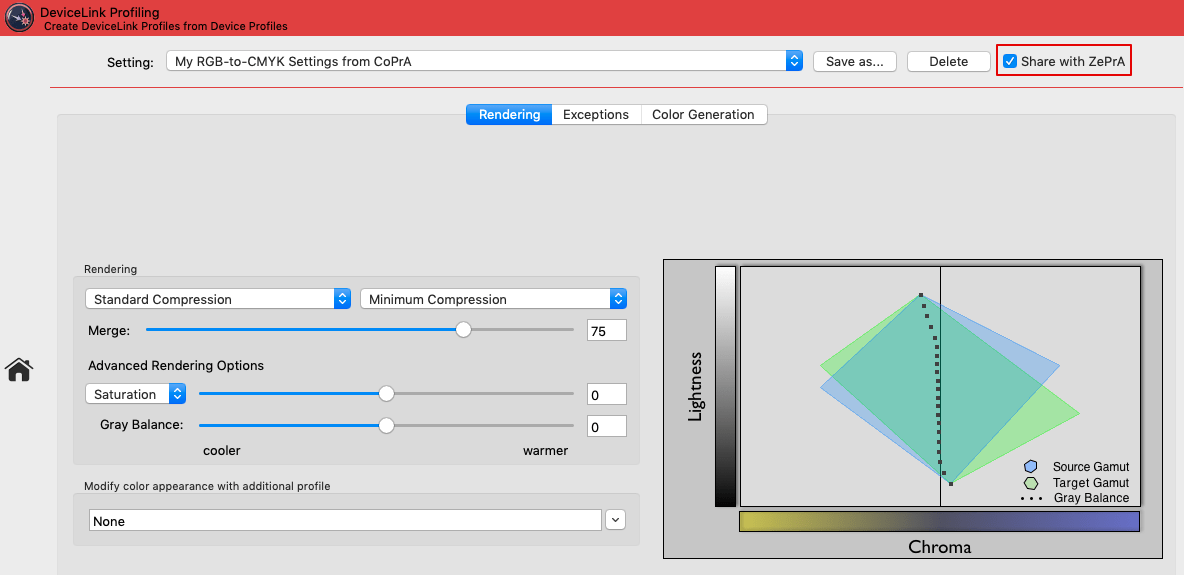

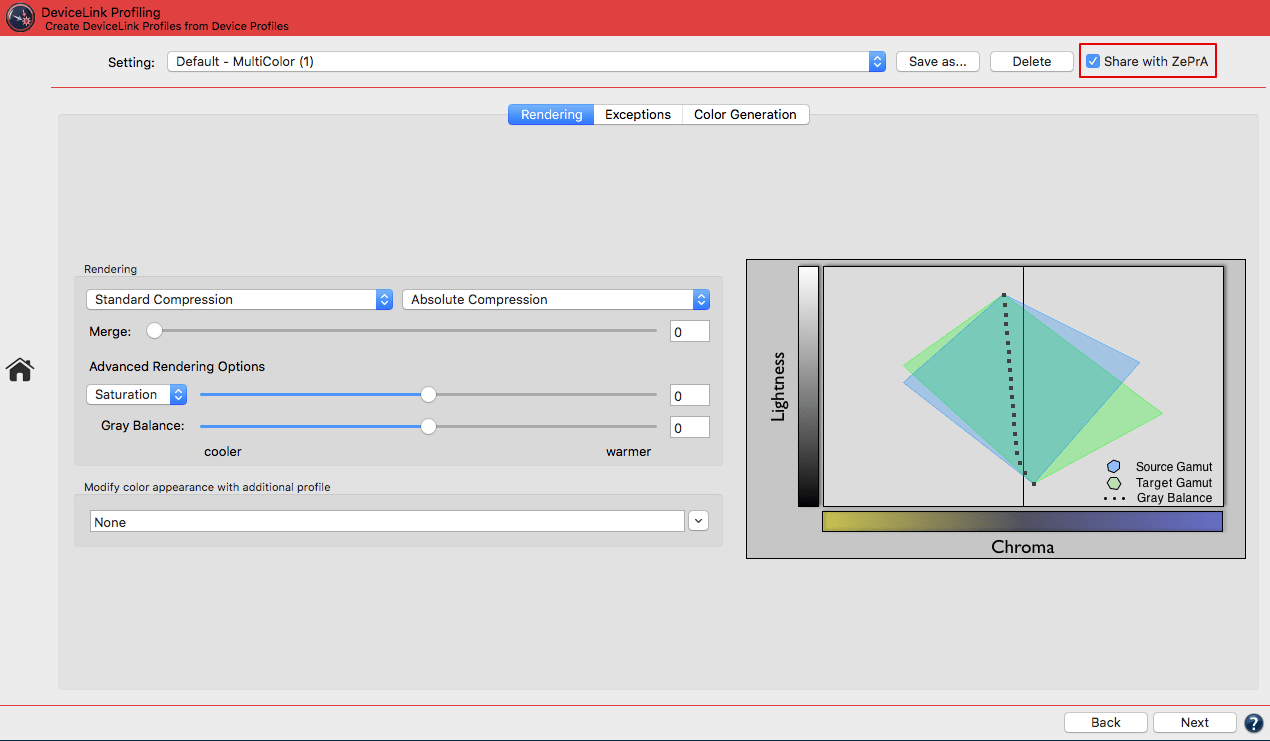

Sharing settings with ZePrA (CoPrA 5 and lower)

Due to the close connection between CoPrA (ColorLogic’s profiling solution) and our color server ZePrA, the profile settings from CoPrA can be used to calculate DeviceLink profiles in ZePrA.

By selecting the checkbox Share with ZePrA in CoPrA, the settings of your DeviceLink and SaveInk profiles are transferred directly to ZePrA and can be used there as SmartLink Method.

The SmartLink Method in ZePrA allows calculation of the necessary DeviceLink and/or SaveInk profiles for the conversion of PDF files on-the-fly, without the need to create these DeviceLinks in advance.

The DeviceLink tool in CoPrA: SmartLink can use the profile settings from CoPrA to create DeviceLinks in ZePrA

To do so, make all the required settings in CoPrA by entering all relevant information in the DeviceLink tool under Rendering, Exceptions, and Color Generation. Click Save As and enter a name for the setting. Confirm with OK, then activate the Share with ZePrA checkbox.

The so created methods shared with ZePrA are then available as SmartLink Method in the drop-down menus of both the Auto Setup and the Configurations.

Note: Only saved settings can be shared with ZePrA. Default or edited presets cannot be shared.

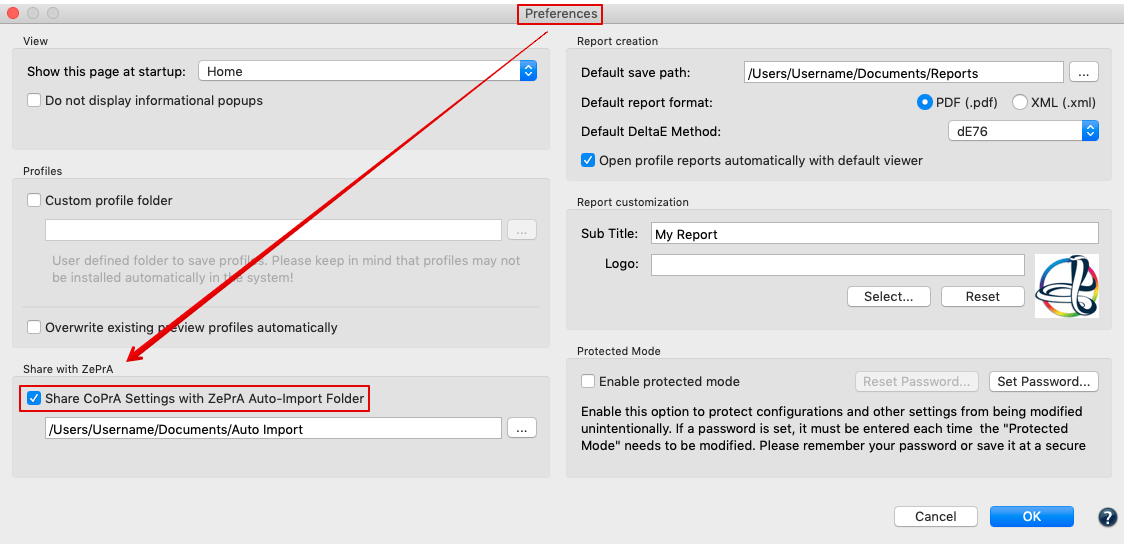

Sharing settings with ZePrA (CoPrA 6 and higher)

The SmartLink Method in ZePrA allows to create DeviceLinks and SaveInk profiles for the conversion of PDF files on-the-fly, without the need to create these DeviceLinks in advance.

Due to the close linkage between CoPrA and ZePrA, profiling settings specified in CoPrA can be used by ZePrA to create the required profiles.

The settings are accessible via a shared folder which has the advantage that CoPrA and ZePrA do not need to be installed on the same computer. The shared folder must simply be accessible by both ZePrA and CoPrA, either over the network, a shared local folder or the cloud.

Procedure

In CoPrA

- Under Preferences, enable the checkbox Share CoPrA Settings with ZePrA Auto Import Folder and select ZePrA’s Auto Import folder.

Note: The Auto Import folder must be activated in ZePrA as well.

If the checkbox is enabled and the Preferences dialog closed with OK an information message will appear asking the user if all shared presets should now be copied to the defined Auto-Import Folder.

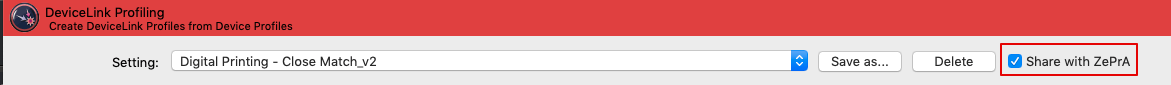

- In the DeviceLink tool, define all required settings by entering all relevant information under Rendering, Exceptions and Color Generation.

- Click Save As and enter a name for the setting. Confirm with OK, then activate the Share with ZePrA checkbox.

- CoPrA Settings created that way and shared with ZePrA are available for selection as SmartLink Method in the drop-down menus of both the Auto Setup and the Configurations settings.

Note: Only saved settings can be shared with ZePrA. Default or edited presets cannot be shared.

In ZePrA

Make sure to enable the Auto Import function in ZePrA’s Preferences and to use the same folder as CoPrA. CoPrA’s DeviceLink and SaveInk settings are now accessible in ZePrA and can be used there as a SmartLink Method. SmartLink can now create custom DeviceLinks which can be used in ZePrA configurations.

Basic information on the Auto Import folder

Files (such as ICC profiles, configurations, spot color libraries, gradations or SmartLink settings) that are moved or copied into the Auto Import folder are transferred to ZePrA’s internal dataset and can then be used by ZePrA.

When the file in the Auto Import folder is replaced by a newer version, it will be updated in ZePrA’s internal datasets as well.

Note: If a file in the Auto Import folder is deleted, it is not deleted in ZePrA’s internal dataset. For example if a SmartLink setting has been deleted in the Auto Import folder, it is still available in ZePrA’s internal dataset and if this setting is deleted in ZePrA’s dataset, it is still available in the Auto Import folder.

Document Color Space

The document color space serves as a reference to define a uniform color space for the colors of the PDF file.

- CMYK color spaces are usually used for print production, as CMYK colors are generally used for printing.

- RGB document color spaces are suitable for modern publications for mobile media.

- Multicolor color spaces are often used in packaging printing or in modern digital printing.

ZePrA supports the full spectrum of color spaces (Multicolor color spaces require a Multicolor license). Individual RGB or CMYK objects with embedded profiles in PDF files are converted to the document color space. For professional print production, data exchange should always be based on the PDF/X standard.

Prefer Output Intent

By activating this checkbox, the output intent of the PDF/X file is used instead of the manually set Document Color Space.

In addition to the ICC device profiles of individual PDF objects, an output intent can be defined for the entire PDF document (an ICC device profile that describes the document color space).

The document color space in PDF/X documents is clearly defined as the output intent.

If Prefer Output Intent is activated, PDF/X files with various output intents can be correctly converted in a queue because the respective output intent is considered instead of the document color space.

Note: This function is only applicable for PDF/X files.

Rendering Intent

General information on the design of ICC device profiles

Rendering intents, such as Perceptual or Relative Colorimetric, contain large tables which, for example for CMYK profiles, convert either CMYK color values to Lab or Lab color values to CMYK.

Due to these two color conversion directions, there are two tables for each rendering intent. The tables are calculated from the measurement data when a color profile is generated.

If ICC device profiles are calculated from the same measurement data, but with different profiling programs, then the tables generated can differ considerably in some color ranges.

This is especially true for the two tables of the Perceptual intent, for the gray balance and also for the areas with very high color saturation in the two tables of the Relative Colorimetric intent (also called “Out of Gamut” colors).

For optimal and harmonious color conversion, it is recommended, especially with CMYK-to-CMYK color conversions, to ensure that the source and target profiles were calculated with the same profiling software.

However, profiles from different providers (such as Adobe, ECI or ColorLogic) are often used in practice, which can lead to problems in color conversions if the perceptual rendering intent is used.

These problems can be avoided by using SmartLink.

The SmartLink module uses the source profiles embedded in PDF or image data and automatically calculates the DeviceLink profile required for conversion between source and target for each object and applies it at object level. The main conversion from the document color space to the target color space is also carried out via SmartLink. SmartLink is ideal for processing external data from a wide variety of sources to ensure optimum color accuracy (via DeviceLinks).

Additional SmartLink Rendering Intents

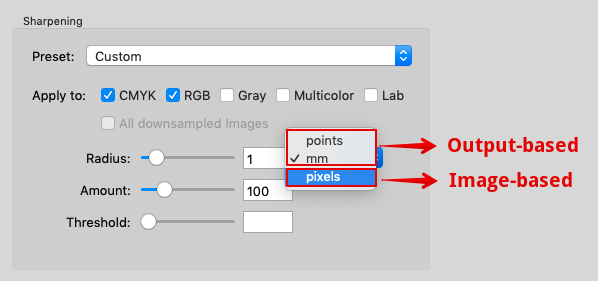

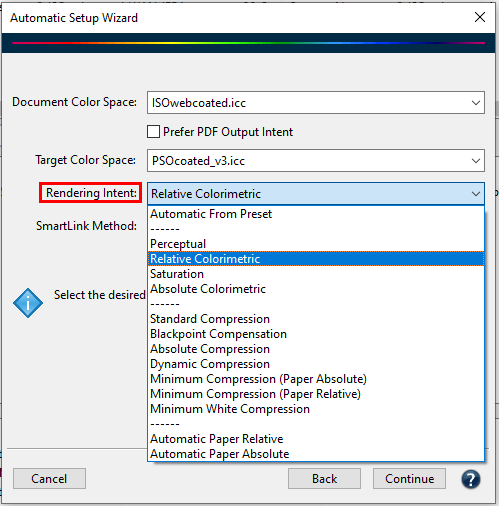

There are several additional Rendering Intents for SmartLinks

The SmartLink module provides several additional rendering intents to avoid inharmonic color conversions, which can result from differently calculated tables for source and target profiles.

To ensure precise color conversions, ZePrA completely recalculates the conversion of source and target profiles on-the-fly. The algorithms are the same as ColorLogic’s CoPrA profiling software.

Note: These additional rendering intents are only available with SmartLink enabled. If the checkbox Use SmartLink is not activated or SmartLink has not been licensed, only the four standard rendering intents are available.

Automatic from Preset: This option is for Custom SmartLink Methods shared from CoPrA and takes whatever setting has been selected in the shared DeviceLink setting from CoPrA, including the rendering options, like a merge between two rendering options, chroma or saturation boosts, all exceptions and black generation settings.

Note: Automatic from Preset is only available in the drop-down menu when a custom SmartLink Method is selected. So, first select a custom SmartLink Method and the option Automatic from Preset will be on top of the list.

Note: In earlier versions of ZePrA (9 and lower) it is not possible to merge two different rendering options for color conversion, because the rendering settings of a profiling setting shared from CoPrA are always overwritten by the rendering setting selected in ZePrA.

Standard Compression: This is the default method. It uses a perceptual conversion that is well suited for all types of gamuts, i.e., also for conversions between color spaces of different sizes. Neutral tones are converted using a relative colorimetric approach, and the appearance of the gray axis always depends on the paper white of the target profile. Therefore, the gray axis of the transformed file will appear yellowish on a very yellowish paper. The same gray axis will appear bluish on a bluish paper. For very small color gamuts, for example in newspaper printing, the dark tones are raised slightly to achieve more image definition in these areas.

Black Point Compensation: Use Black Point Compensation to achieve the same results with a perceptive conversion as with “Relative Colorimetric with Black Point Compensation”. When converting from large to small color spaces, the image definition is preserved in the highlights and shadows, unlike with a pure Relative Colorimetric conversion. Neutral tones are converted using the Relative Colorimetric intent. Out-of-gamut colors are cut off.

Absolute Compression: This method is based on the absolute colorimetric rendering intent in terms of color reproduction and is recommended when the paper tones differ significantly (the color gamuts can be similar or different). In contrast to the Standard Compression and Black Point Compensation, the paper tint is compensated in the gray balance. The rendering of neutral colors is based on the absolute colorimetric rendering intent, without paper tone simulation in the highlights. If, for example, the paper white is significantly more yellow than in the reference, the gray axis appears neutral despite the yellowish paper tone. This ensures that the color appearance of the original file is preserved as best as possible on a target medium with a different paper tint. The contrast range in the highlights and shadows is adapted to avoid any loss of image definition.

Minimum Compression (Paper Absolute): This method is largely similar to the absolute colorimetric intent and only compensates close to the black and the white point.

In addition, the white point of the source color space is not simulated, but scaled to the white point of the target color space, thus ensuring a pure paper white.

Use this rendering intent to achieve a close reproduction, for example when using print standards such as ISO Coated V2 or GRACoL2006 Coated1v2 on a digital printer.

Note: As for the absolute colorimetric rendering intent, ensure that the target color space is larger or has at least a similar size to avoid any loss of image definition. For color conversions from larger to smaller color spaces use Absolute Compression to maintain the gray balance of the source color space.

Minimum Compression (Paper Relative): This method is largely similar to the relative colorimetric intent and only compensates close to the black and the white point. It is similar to Minimal Compression (Paper Absolute) but uses relative colorimetric instead.

Dynamic Compression: Compares the source color space with the target color space and generates a compression that minimizes out-of-gamut areas. This setting preserves the brightness of the original color space while reducing the saturation, and therefore also preserves the image definition. As for the Standard Compression, the gray axis of the conversion is built relative to the paper white of the target profile. This approach is well suited when the source and target profiles have a very large dynamic range and contrast, for example, in RGB-to-CMYK conversions.

Note: This method is now only available in ZePrA for compatibility reasons, and no longer in CoPrA. We recommend using Automatic Paper Relative instead.

Minimum White Compression: This method is similar to Minimum Compression (Paper Absolute). Both rendering intents compress the white point without paper simulation, however, there is an important difference: The Minimum Compression is a rather perceptual rendering that additionally compresses the black point, so the maximum dynamic range is utilized without loss of detail in the shadows. In contrast, the Minimum White Compression compresses the white point but not the black point, so a close absolute colorimetric match between source and target color spaces can be achieved. This can be useful for the color representation across various media, color matching or printing on slightly differing media. It can be regarded as close to absolute colorimetric rendering without paper tint simulation.

Note: Remember that the target color space should be larger than the simulated color space (or similarly large) to avoid loss of detail and vividness (similar to the absolute colorimetric rendering intent). For conversions from large to small color spaces, instead use our rendering intent Absolute Compression if the gray balance of the source color space is to be preserved.

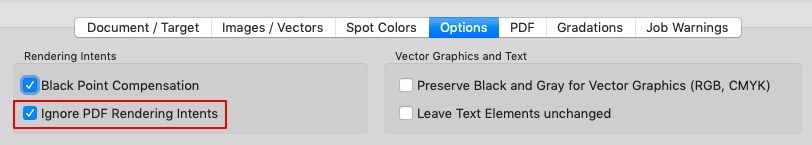

Important: To ensure that an on-the-fly DeviceLink profile created with SmartLink uses the rendering intent set under Configurations > Images/Vectors, activate the checkbox Ignore PDF Rendering Intents in the Options tab.

Automatic Paper Relative: A paper-relative rendering without adjusting the gray balance, which differs between the source and target profiles due to differences in paper tone. A typical use case would be a more colorful rendering of a color space on a different printer where the gray balance does not necessarily need to match. For example, a campaign that has been prepared for ISO coated V2 but is to be printed on a large format inkjet printer. The gray balance is reproduced with the same coloration as the paper color tone of the target profile.

Automatic Paper Absolute: An absolute paper rendering with consideration of the paper color tone. A typical use case would be the same as Automatic Paper Relative, but with the paper color tone of the source profile taken into consideration. This results in a reproduction of the gray balance on the target printer that matches the color tone of the source profile and thus provides the best possible color appearance.

Important: For PDF processing ZePrA typically uses the rendering intent defined in the PDF for each object. When deviating from this rule, ensure that an on-the-fly DeviceLink profile created with SmartLink uses the rendering intent set under Configurations > Images/Vectors, select the checkbox Ignore PDF Rendering Intents in the Options tab.

SmartLink Method

The SmartLink Method considers the different requirements of different printing conditions so the printed color is correctly reproduced and optimally separated for the printing process.

Traditional Printing – Classic: Conversions for offset, gravure, or newspaper printing. The DeviceLinks created ensure that black and gray, as well as the primary, secondary and triplex hues of the source profile, are preserved. The total area coverage is taken from the target profile.

Choosing a SmartLink Method

Traditional Printing – Automatic: Select this setting when the colors and paper of the target color space are significantly different from the output intent or document color space. Separation is preserved, but Exceptions for special colors such as black and gray, primary, secondary, and triplex colors are automatically calculated based on both profiles.

Large Format Printing – Inkjet: The separation is characterized by a strong GCR and a late black start. The black point and total area coverage are automatically calculated to ensure the best color reproduction. The Exceptions for special colors, such as black and gray, primary, secondary and triplex hues, are automatically calculated based on both profiles. To avoid problems that can occur when colors vary between different inkjet printers or between the inkjet printer and the source color space (as with ISOcoated V2 or GRACol), the Large Format Printing – Inkjet method automatically calculates the required exceptions in those cases.

Digital Printing – Toner: For toner-based digital printers and office printers. This method uses the same DeviceLink presets for Exceptions as Large Format Printing – Inkjet. The separation method ensures that a high percentage of black is used. This will achieve a stable print and neutral gray balance. The total area coverage is taken from the target profile. The Exceptions for special colors, such as black and gray, primary, secondary, and triplex hues, are automatically calculated based on both profiles.

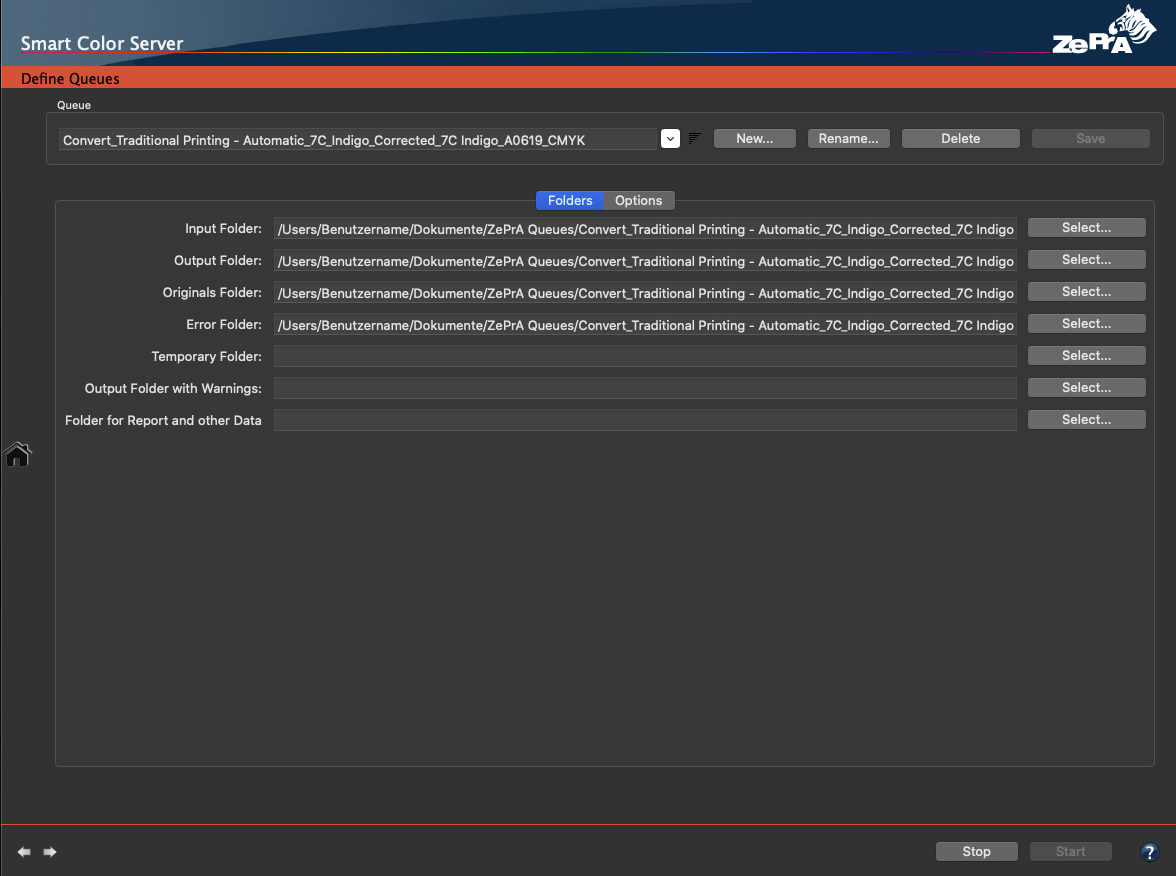

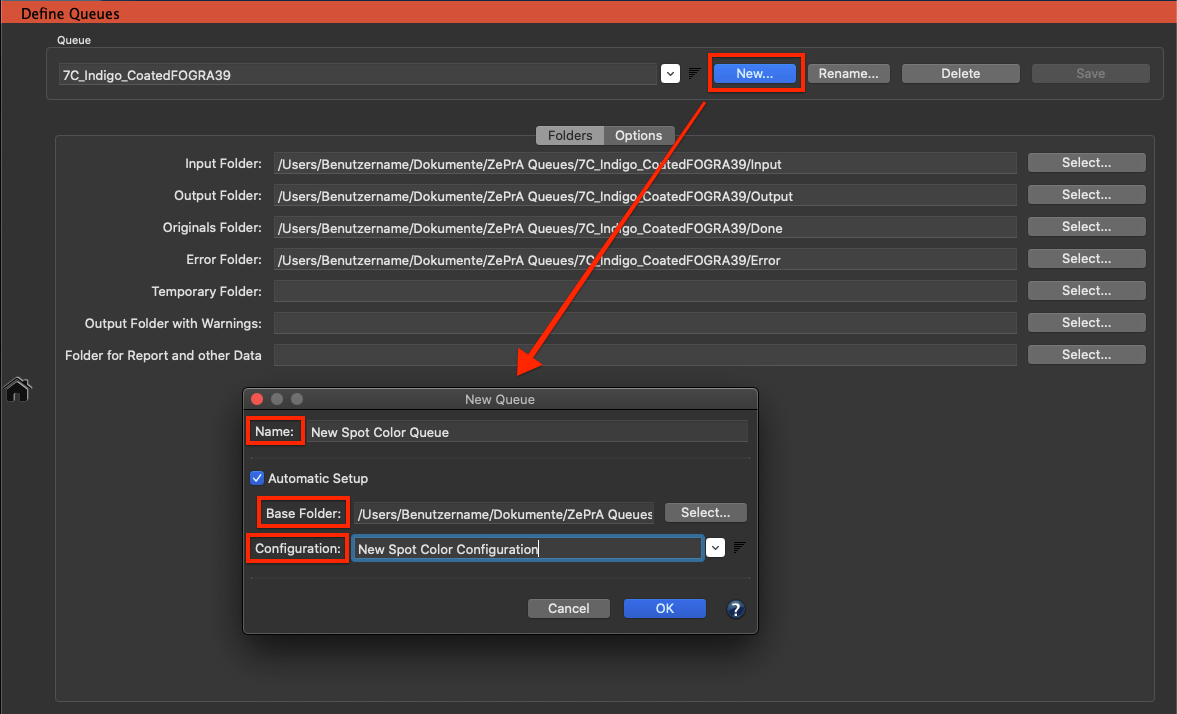

Creating Queues and Configurations

Creating Queues and Configurations

- Enter a Queue Name that matches the name of the configuration.

- Specify the Base Folder in which the queue is to be created. To create a Queue (Hotfolder) in the Base Folder, activate the Create Queue checkbox and the corresponding subfolder will be created.

- To only create a new configuration, uncheck the Create Queue checkbox. The new configuration can be assigned to an existing queue in the Queues dialog later if required.

Note: Auto Setup overwrites configurations without warning.

If a configuration with the same name is to be overwritten, a warning only appears if the existing configuration or queue has different settings. If the settings are identical, the configuration is overwritten without warning.

In the final step of the Auto Setup the queue is created along with all required folders

Configurations

All settings related to color handling and PDF processing are defined under Configurations. This includes color conversion via ICC output profiles or DeviceLink profiles, handling of mixed PDFs (documents with data in CMYK, RGB, Grayscale and spot colors) and individual settings of gradation curves and spot colors. Various presets and optimization options are available for all settings.

In the upper part of the window, select a configuration, create, rename and save new configurations.

To duplicate an existing configuration, select New, enter the new name and Save. To use a duplicated configuration, assign it to a queue.

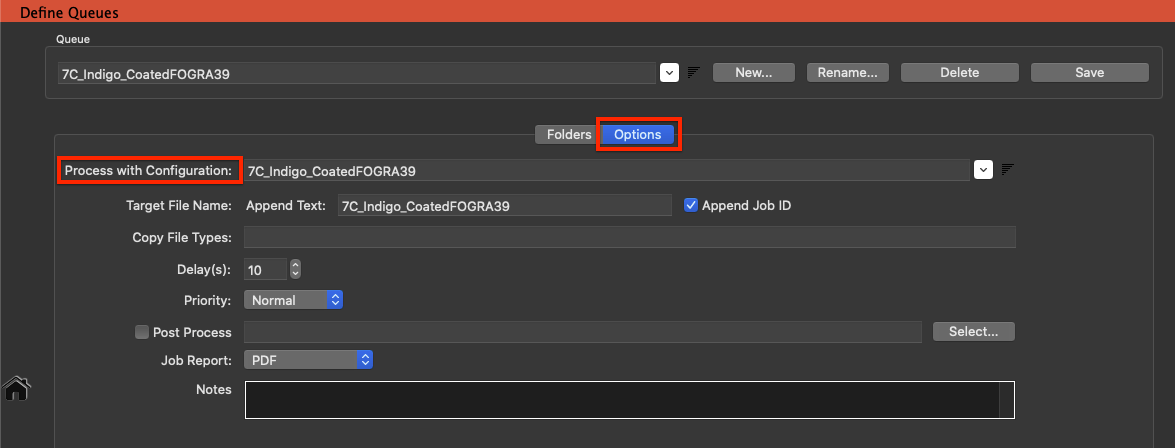

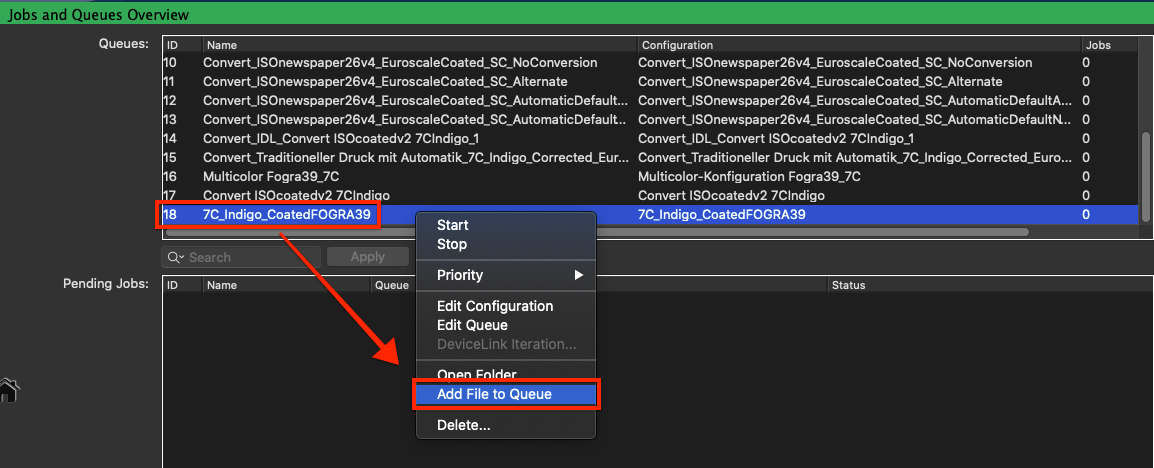

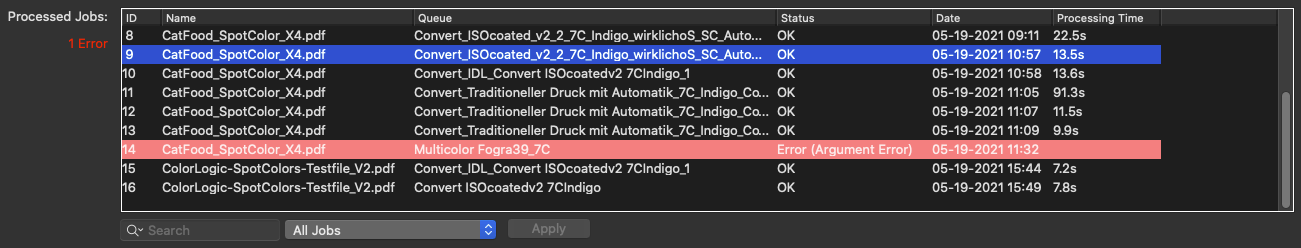

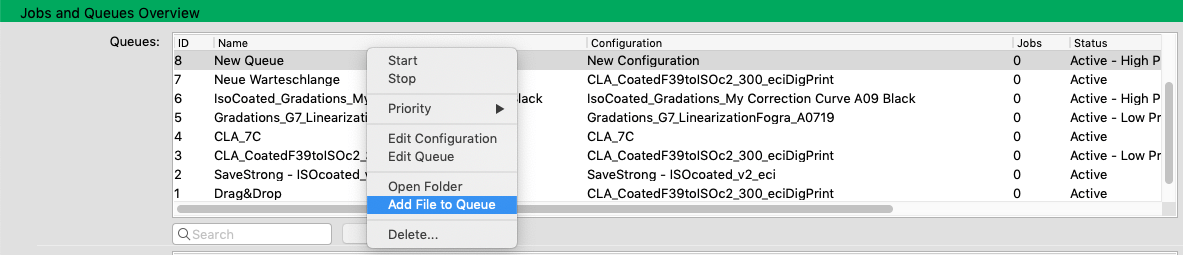

Using Queues

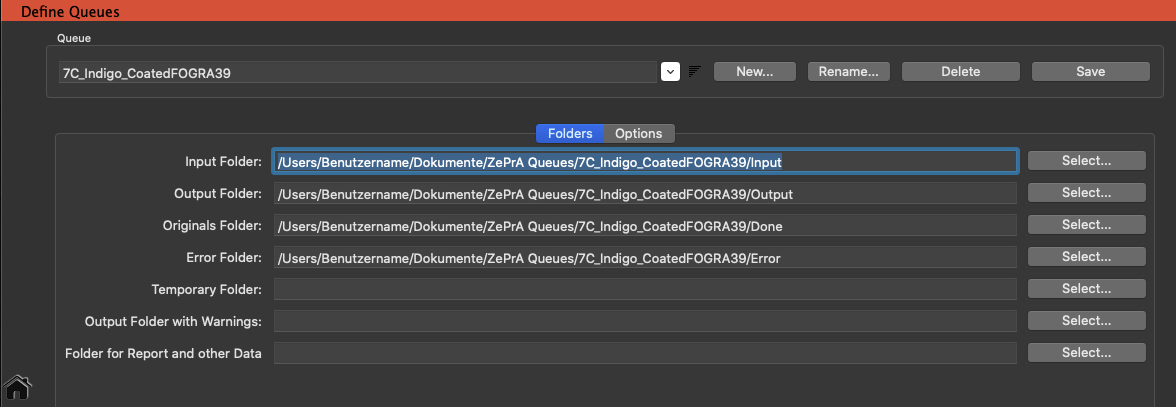

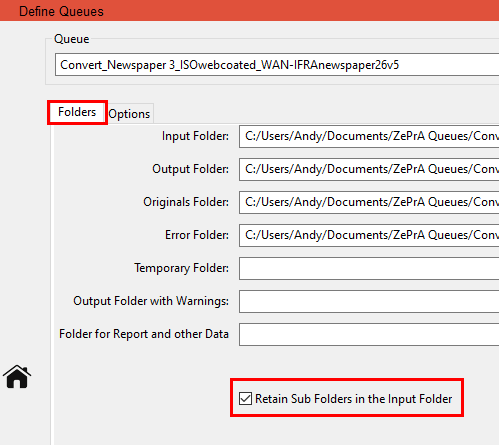

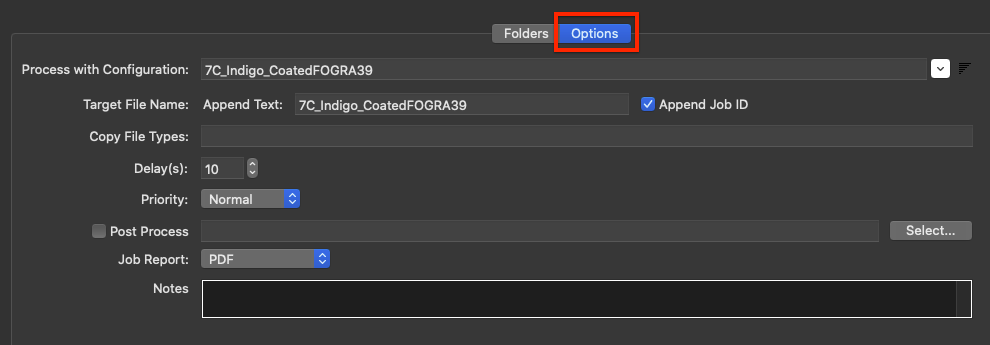

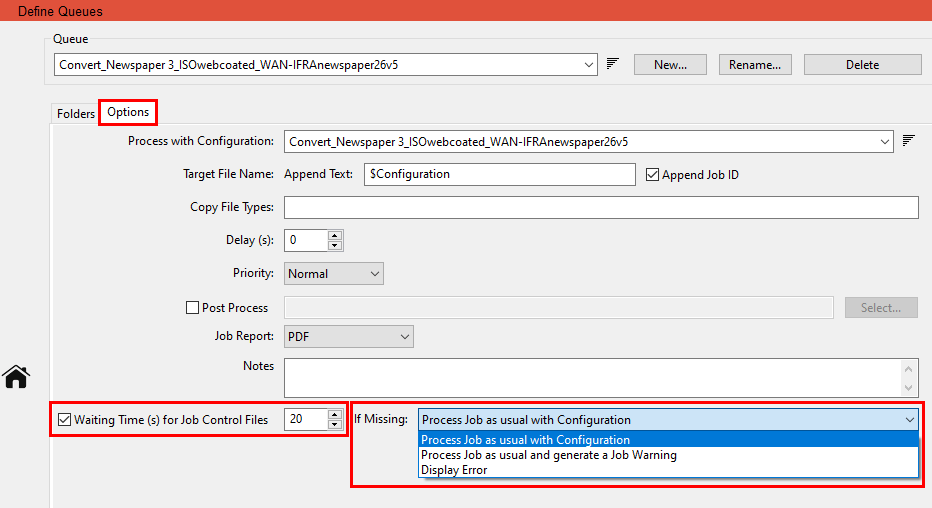

The Automatic Setup Wizard simplifies the setup process, once complete, the new configuration and queue can be used immediately. To use a queue, simply copy or move the PDF file to be converted to the Input Folder of the queue.

The queue is automatically started by placing a file in the hotfolder

PDF files in the Input Folder are automatically converted according to the color management settings and saved to the Output Folder. Original files are moved to the Done Folder. Files that have caused an error are saved in the Error Folder.

General Information

General Information on Normalization

When a normalizing mode is selected, the Document Color Space is the same as the Target Color Space and no conversion between document and target takes place. However, all images and vectors color spaces deviating from the Document Color Space profile are first standardized, e.g., converted to the document color space or output intent. This is called normalization.

With PDF/X files, all ICC-based PDF objects are converted from the embedded ICC profile via the embedded rendering intent to the document color space (output intent). After this step, all objects of the PDF file have been converted to a consistent “standard” (Document Color Space/Output Intent).

PDF files generally do not contain any information about the document color space (Output Intent). If there is no PDF/X file available for normalization but only a PDF file, decide on a document color space into which any existing ICC-based PDF objects are converted.

After conversion, the final, normalized file consists only of a color space and spot colors, if present.

The following color conversions are performed during normalization:

- Conversion of device RGB and ICC-based RGB to document color space

- Spot colors remain unchanged (can be converted to the target color space if required)

- Conversion of ICC-based CMYK to document color space, retaining pure colors and separation properties (when using SmartLink)

- Assignment of ICC-based gray to the black channel of the document color space (prevents four-color gray)

Converting PDF files with Auto Setup

The easiest way to set up a color management workflow between various color spaces is to use the Auto Setup in combination with the SmartLink method. ColorLogic’s DeviceLink Sets (DLS) are also an option for standard color spaces. All sets are optimized so that the colors of both image and vector data of a PDF file can be reliably converted. The profiles are optimized and checked for smoothness and visually correct conversion, and have been proven in production.

All color information required for PDF/X is automatically set by Auto Setup, including the use of the target profile as output intent, normalization, and color conversion.

Gradients in vector graphics that consist of just one or two CMYK colors still contain only the original colors after application of the profile. The color values are merely adjusted for the output.

Example: If PDF objects are in the RGB color space and the Relative Colorimetric rendering intent is embedded, the Auto Setup queue automatically activates Black Point Compensation to ensure accurate detail reproduction in shadow areas.

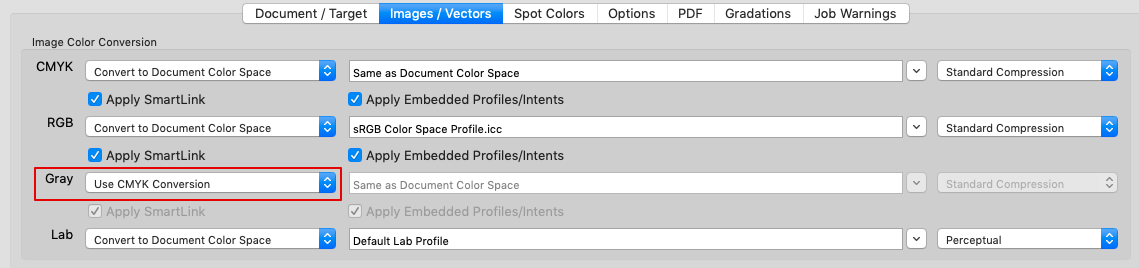

Grayscale: Grayscale objects can be handled like CMYK, preserving gray and avoiding conversion to four colors. To do this, choose Use CMYK Conversion

from the drop-down menu Gray in the Images/Vectors tab under Configurations. If SmartLink is licensed, color conversions of objects with embedded profiles are always performed via SmartLink to ensure the best possible quality.

Spot Color: If the PDF files contain spot colors, they remain unchanged. To convert spot colors to process colors, the spot color settings must be adjusted under Configurations > Spot Colors.

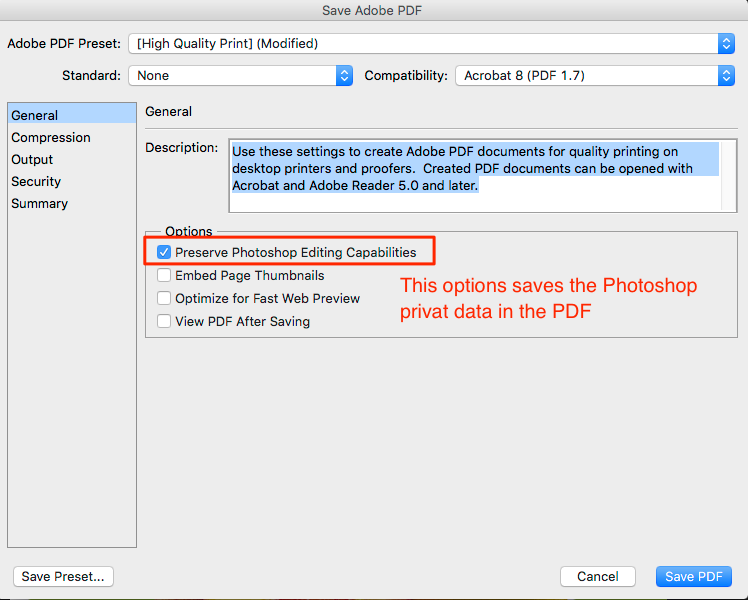

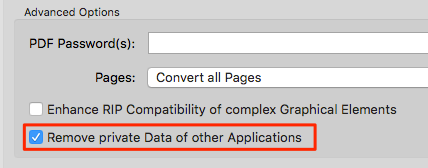

Embedding profiles: By default, no ICC device profiles are embedded in the individual elements of the output file.

SmartLink: If the SmartLink function has been licensed, color conversions of objects with embedded profiles are always performed via SmartLink and use DeviceLink profiles in order to guarantee the best possible quality.

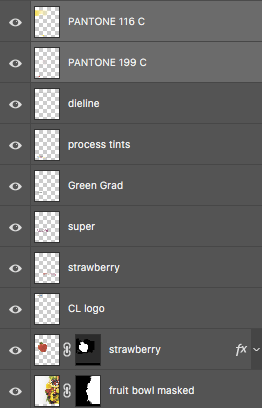

PDF Transparencies: If a PDF file contains transparencies, the individual PDF objects are processed in exactly the same way as the PDF files without transparencies. The colors of the transparencies are converted by default and the transparency information is preserved unchanged. If required the Transparency Flattening can be set in the configuration in the PDF tab under Transparency/Overprinting.

Flattening is mainly required for transparent objects if there are problems after conversion while maintaining transparency and when spot colors are to be converted to process colors.

Converting Image Files with Auto Setup

TIFF, JPEG, PSD, or PSB image data are processed in auto setup queues the same way as image data of a PDF file. The conversion is based on the settings under Images/Vectors and Document/Target.

For pure image data conversion of TIFF, JPEG, PSD and PSB images from a source color space to a target color space, it is recommended to use the Auto Setup option Direct Color Conversion to new Output Condition and select one of two options in the Automatic Setup Wizard:

Option 1: Use a previously created DeviceLink profile for the conversion of the image color space to the target color space. The DeviceLink chosen in the Automatic Setup Wizard should be set to source profile of the image, for situations where images without embedded profiles are processed. The target profile is set by the Auto Setup.

For images with embedded profile and images with other color spaces not defined under Document Color Space the settings under Images/Vectors are applied. Make sure to select the proper default profiles, the desired rendering intent and make sure that the checkboxes under Apply Embedded Profiles are enabled.

Option 2: Use ICC Profiles for document color space and target color space to calculate a DeviceLink “on-the-fly” via SmartLink, which requires a license for SmartLink. Choose the desired Rendering Intent and SmartLink Method for the calculation.

When using the SmartLink option, either a DeviceLink profile is created “on-the-fly” or a stored DeviceLink profile is used depending on the setting under Profile Assignments. Store the specific profile in the table in the Profile Assignments window to ensure that a specific DeviceLink profile is applied in the configuration.

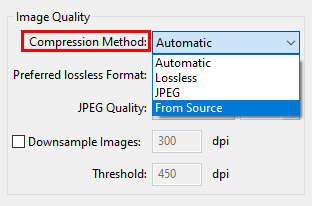

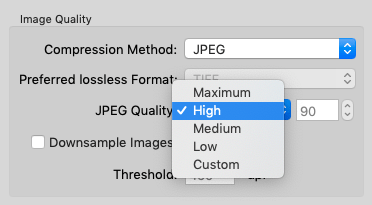

Additional information regarding image files

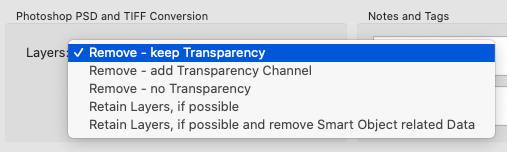

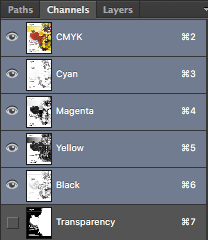

ZePrA supports images with 8 bit and 16 bit color depth. The color depth of the input data is preserved with the conversion unless TIFF, PSD or PSB files are saved as JPEG files under Options/Image Quality. This will result in a color depth of 8 bit since only 8 bit is possible in JPEG files. Read more about this under Configuration > Options > Image Quality. ZePrA supports layers in PSD and TIFF files. Read more about this under Configuration > Options > Photoshop PSD and TIFF Conversion.

General Information

For high-quality color conversions, the source color space of the object to be converted should be known or readable. If no suitable document color space (ICC Output Intent) is assigned to the objects of the PDF file, the conversion is performed based on the document color space selected as source profile. Be sure to select a suitable document color space, as an unsuitable document color space will affect the quality of the conversion.

In most cases, Auto Setup converts PDF files to an output color space without assigning an embedded profile to each element. The output depends on the target profile (CMYK, RGB, Gray or Multicolor).

Data containing additional spot color information is not changed in a standard queue. All color information required for PDF/X is automatically set in Auto Setup, including the definition of the target profile as an output condition.

Auto Setup is great for creating queues for common color conversions. However, if the workflow requires special adjustments, changes can be made as needed under Configurations.

In the Queues chapter, you can learn more about how to handle the hot folders created by the Auto Setup Wizard or the Queues tool.